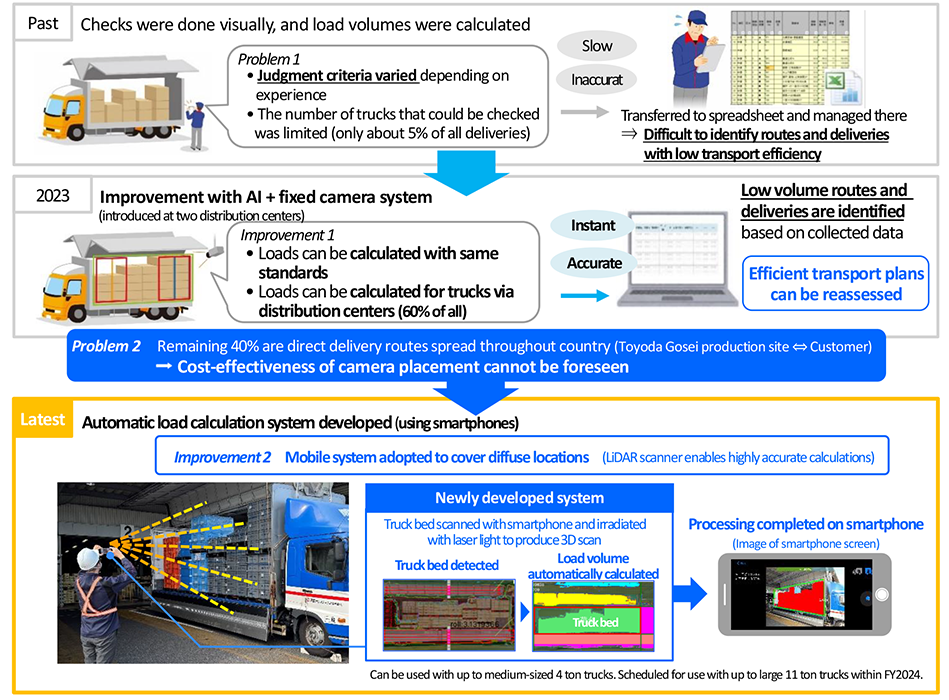

Toyoda Gosei Co., Ltd., as one part of its efforts to improve transport efficiency during product delivery, has developed a system that uses smartphone 3D sensing (LiDAR) to easily calculate truck load capacity without place restrictions.

When planning truck allocation and routing at present, load volumes are regularly checked for optimization based on production volumes at each of the plants of Toyoda Gosei’s automaker customers. Previously, a person in charge of each route confirmed cargo beds visually, but judgment criteria varied and the number of trucks that could be checked was limited. To deal with these issues, in 2023 Toyoda Gosei developed a 24-hour-a-day automatic load calculation system using AI and fixed cameras. This system was introduced at two distribution centers that account for sixty percent of the company’s product transport, raising loading efficiency.

The newly developed load calculation system is easy to use anywhere since processing can be completed on a smartphone, and highly accurate calculations can be done with a LiDAR scanner. Using this mobile system, efforts to improve transport efficiency will be spread to direct delivery and other routes from Toyoda Gosei’s production locations dispersed throughout the country, which account for the remaining forty percent of product transport.

For similar news, please refer,

Priority Tire is entering a New Market with EV Tires

Lion Electric unveils the groundbreaking Lion8 Tractor