Do you know about the simple definition of the manufacturing industry? It is raw materials get converted to goods, products as per the demands of the audience. The process happens either by machinery or by animal or human labour. This industry is also involved with other types of work. The best examples are installation/ repair of equipment. On some occasions, the manufacturing industry takes up contract operations for other parties. Technologies change with time. AI has brought drastic positive changes in every sector (including manufacturing and healthcare). This blog explains the way AI improved productivity in the manufacturing sector.

.

History of Manufacturing

We will take a few minutes to go into the positive impact of AI in the manufacturing sector. Can we first turn the pages of history in manufacturing? The reason, the facts will help you not only to understand, but gain positive insights into the role of AI in the sector.

The manufacturing industry used human/animal labour in the initial stages of civilization. With the Industrial Revolution, workers used steam/water power to complete tasks. Ford introduced assembly lines for fast production of cars in the automotive industry.

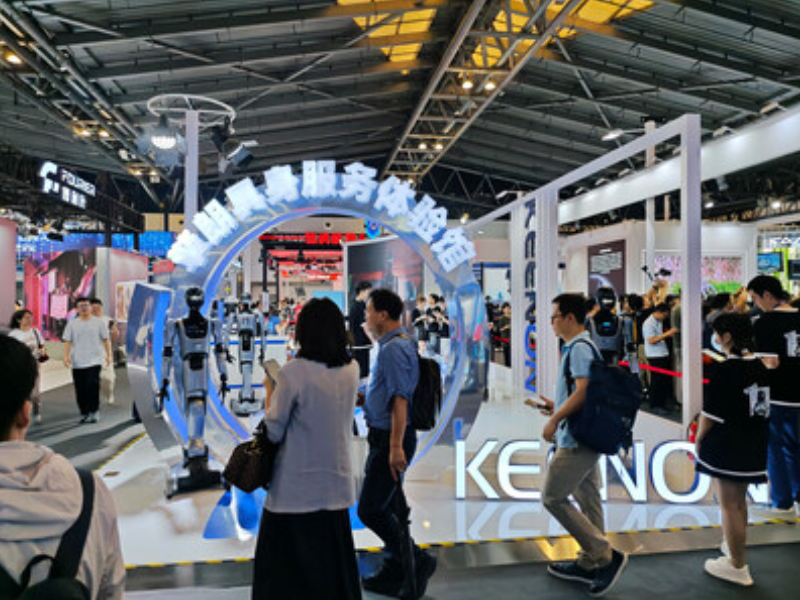

The second breakthrough happened with the introduction of computers. The productivity levels increased due to the introduction of software, the internet and IC chips. Today, robotics, cloud computing, IoT have helped to expand the manufacturing industry to new horizons.

.

.

Two ways AI is changing the manufacturing industry

1. Operational efficiency

The first positive impact AI brings is that it has removed repetitive tasks. AI, with its ability to take care of the machines, gets used to performing repetitive manual tasks. Human labourers and engineers can work on complex machines and tasks.

AI tools help reduce energy consumption by proper scheduling of operating equipment. AI can identify downtime, and if needed, can schedule repairs for weekends. Sensor Data helps the management identify the equipment that will go on the road to failure. So, if maintenance is given at the proper time, the machinery will work without a break.

.

2. Proper Quality Control and Supply Chain Management

AI can detect defects in equipment with more accuracy than the human eye. The same applies to manufacturing products. AI ensures products get manufactured as per the standards of government agencies.

Experts use AI software to analyse customer data and predict product demand. This ensures that products do not get manufactured more than the customer demand.

AI can also streamline logistics via tracking supplies. It can also provide accurate information about bottlenecks. This data provides the management with more visibility and transparency. AI can help make significant changes in the production, distribution and maintenance to generate profits.

.

Future of AI

AI has undergone a tremendous transformation into many types. They are:

As per Capabilities

- Narrow AI

- General AI

- Superintelligent AI

As per Functionalities

- Limited Memory

- Theory of Mind

- Self-Aware AI

As per Technology

- Expert System

- Computer Vision

- Robotics

- Natural Language Processing

- Deep Learning

.

The Future of AI in Manufacturing

The future of AI for manufacturing looks promising, with continuous advancements in AI development expected to drive further innovation. AI development companies are exploring new ways to leverage AI. These companies are inventing new ways to integrate software with industrial equipment (example – IoT).

.

Conclusion

AI has revolutionized the manufacturing sector in various categories such as predictive maintenance, quality control, supply chain and energy management. This has led to an increase in productivity and cost savings for the manufacturing sector.

Blog by Sathya Narayana B.